1. Structure and working principle of stainless steel needle valve

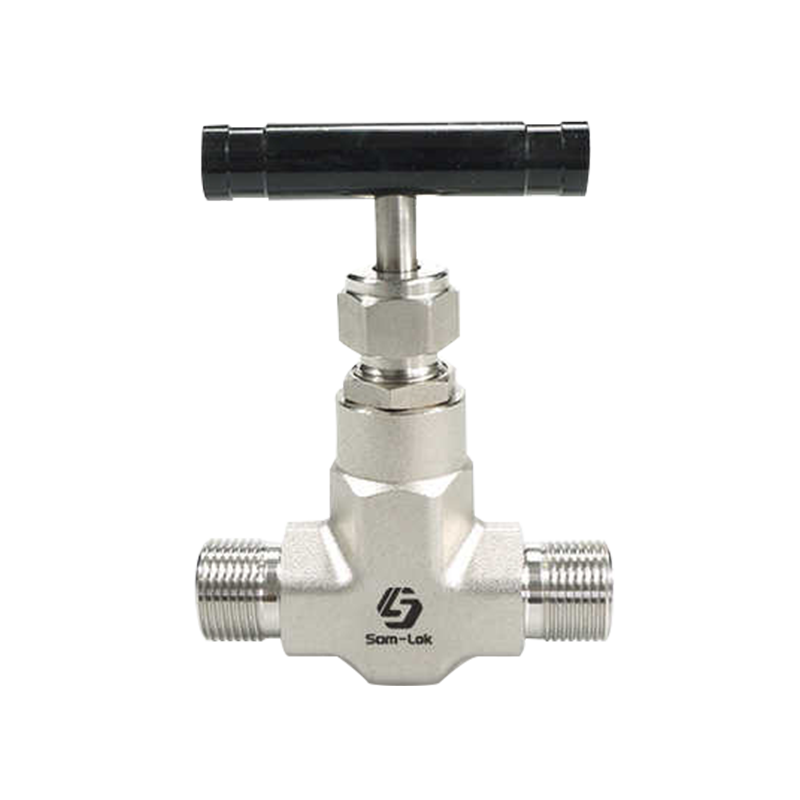

The stainless steel needle valve is a precision flow control device widely used in systems that require precise flow. Its unique structural design mainly consists of a valve body, a valve seat, a needle valve core, a valve stem and a sealing ring. The valve body is usually made of stainless steel, which has excellent corrosion resistance and high temperature resistance, and can adapt to the strict requirements in different industrial environments. The core part of the needle valve is the needle valve core, which presents a slender tip and can accurately adjust the amount of fluid passing through the valve. The valve seat and the needle valve core are closely matched to achieve precise control of the flow by rotating the valve stem.

Nantong Samson Precision Industry Co., Ltd. specializes in the production of high-quality stainless steel needle valves and is committed to providing customers with high-precision control valves suitable for different industrial needs. The working principle of the needle valve is based on the rotation of the valve stem. When rotating, the contact point between the needle valve core and the valve seat gradually changes, thereby adjusting the fluid flow. In this process, the needle-shaped design of the needle valve core ensures extremely high flow regulation accuracy. Compared with other types of valves, stainless steel needle valves can accurately adjust the flow of fluids under very small flow changes, making them suitable for applications that require precise control.

Due to the high strength and corrosion resistance of stainless steel, needle valves can work stably in a variety of harsh environments such as high pressure, low pressure, high temperature, and strong corrosion. Therefore, needle valves are widely used in petrochemical, pharmaceutical, aerospace and other fields to ensure precise control of fluid flow and safe operation of the system.

2. Application fields of stainless steel needle valves

The high-precision flow control characteristics of stainless steel needle valves make them widely used in many industries, especially in environments that require strict flow regulation. Taking the petrochemical industry as an example, in the process of conveying liquids and gases, needle valves can accurately control the flow, prevent excessive pressure or flow imbalance in the pipeline, and ensure safety and stability in the production process. With the improvement of environmental protection requirements, the application of needle valves in wastewater treatment, gas emissions, etc. is also increasing, playing an important role.

In the pharmaceutical industry, stainless steel needle valves produced by Nantong Samson Precision Industry Co., Ltd. are widely used in the filling and flow control of drugs. Since the pharmaceutical production process requires extremely high flow accuracy, needle valves can ensure the accurate dosage of each bottle of medicine in these applications. The corrosion resistance of needle valves makes them suitable for the delivery and control systems of various corrosive chemicals.

High-tech industries such as aerospace, electronics, and semiconductors have extremely high requirements for flow control accuracy. Needle valves meet the stringent requirements for flow regulation in these fields with their unique design. In these industries, needle valves can operate stably under extremely high precision and extreme working conditions and are an indispensable component of critical systems.

Nantong Samson Precision Industry Co., Ltd. not only provides stainless steel needle valves for the domestic market, but also exports to many countries and regions around the world, serving customers all over the world. Our needle valve products help customers improve the reliability and operating efficiency of the system and have become an important choice for many industries.

3. Factors to pay attention to when selecting stainless steel needle valves

When selecting stainless steel needle valves, users need to consider a variety of factors to ensure that the valve can meet the needs of actual applications. Working pressure and temperature are key factors that must be considered when selecting needle valves. Since the working pressure and temperature in different application scenarios vary greatly, choosing a suitable needle valve can ensure the long-term stability of the valve. Nantong Samson Precision Industry Co., Ltd. strictly designs and manufactures needle valves in accordance with industry standards to ensure that each valve can work stably under high temperature and high pressure environments.

Fluid properties are also one of the factors that must be considered when selecting needle valves. Different types of fluids, such as acids, alkalis, oils, etc., may have different requirements for materials and sealing materials. Nantong Samson Precision Industry Co., Ltd. provides needle valves with a variety of different materials and sealing methods to meet the transportation and control needs of various fluids. Our company tailors valve products for customers to ensure that the fluid will not be affected by corrosion or leakage when passing through the valve.

Accuracy requirements are also one of the key factors affecting selection. In situations where very precise flow regulation is required, it is crucial to choose a needle valve with the right accuracy. The needle valve products provided by Nantong Samson Precision Industry Co., Ltd. have been widely praised in the market for their excellent regulation accuracy. We provide the most suitable needle valve type according to user needs to ensure that every customer's application needs can be met.

The connection method of the valve is also one of the factors that need to be paid attention to when selecting. Stainless steel needle valves usually have a variety of connection methods, such as threaded connection, flange connection, etc. Different connection methods are suitable for different pipeline systems. Choosing the right connection method can ensure a good match between the valve and the pipeline, avoiding failures or leakage caused by improper installation.