1. What is the function of stainless steel check valve?

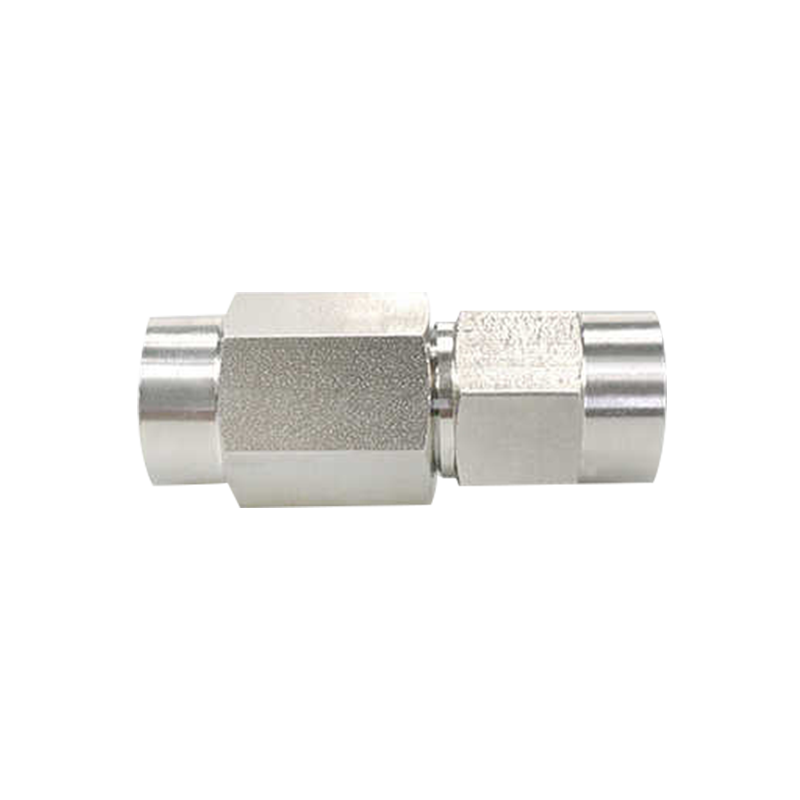

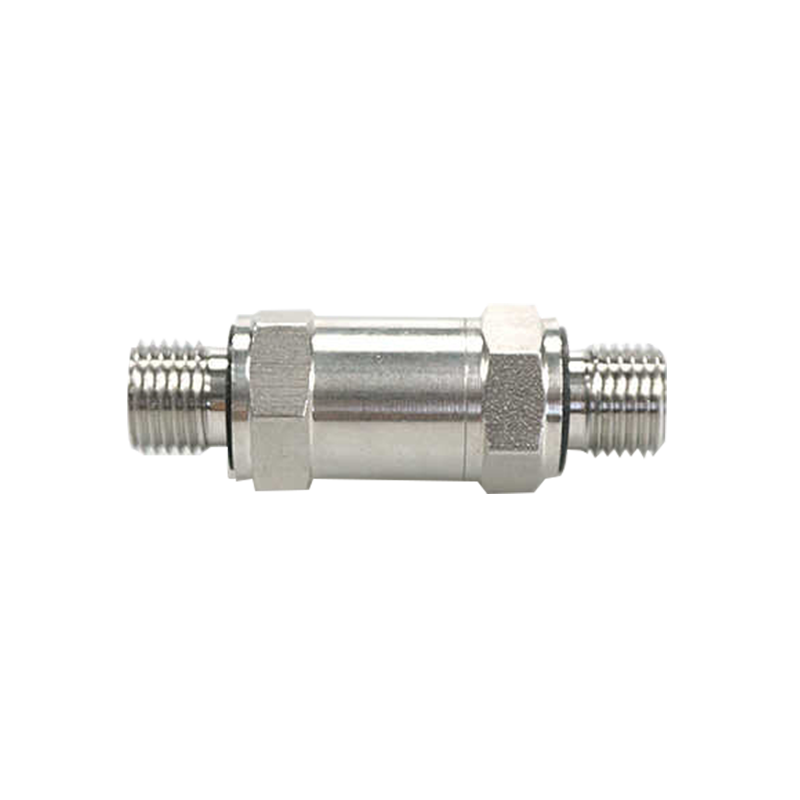

Stainless steel check valve, as an important industrial valve, is widely used in various fluid control systems. It is also called a one-way valve. Its main function is to allow fluid to flow in only one direction in the fluid system and prevent reverse flow. The fluid can only pass freely in the set flow direction, and the reverse flow is completely blocked, which effectively avoids pipeline damage, equipment failure and even safety hazards caused by backflow. Common application scenarios include water treatment, petrochemical, food processing and pharmaceutical industries.

Nantong Samson Precision Industry Co., Ltd. (Samson), as a professional manufacturer of industrial valves and accessories, has been committed to providing customers with the best fluid system solutions. The company has rich industry experience and technical accumulation, and can design and customize check valve products according to the needs of different customers to ensure that each customer's system can operate under the best conditions. Through continuous innovation and optimization of product design, Samson helps customers effectively solve various problems in fluid control and ensure the safety, stability and efficiency of operation.

As a key component in the fluid system, the stainless steel check valve not only has the function of preventing the backflow of the medium, but also avoids liquid contamination, system pressure fluctuations and other possible equipment damage caused by backflow. In order to meet the needs of different applications, check valves can be precisely designed and adjusted according to the flow rate, fluid type and system pressure. Especially in the environment of high temperature, high pressure and corrosive media, stainless steel check valves are particularly important due to their excellent corrosion resistance and high temperature resistance.

Samson has been committed to providing customized solutions according to the specific requirements of customers to ensure that every fluid control system can operate efficiently. With strong R&D capabilities and exquisite manufacturing technology, Samson's check valve products have been recognized and trusted by many industry customers worldwide.

2. How to choose the right check valve opening pressure?

The opening pressure of the check valve is a key parameter that determines whether it can be opened and closed smoothly. Therefore, choosing the right opening pressure is crucial to ensure the normal operation of the fluid system. The opening pressure refers to the pressure value at which the valve begins to open under the action of fluid pressure. Too high or too low opening pressure will affect the use of the valve. The selection of opening pressure needs to consider many factors, including the flow rate of the pipeline, the nature of the fluid, the temperature, and the pressure of the working environment.

In actual applications, different industries and fluid types may have different requirements for opening pressure. For example, in some high-pressure systems, choosing a higher opening pressure can prevent the valve from opening prematurely due to pressure fluctuations, while in low-pressure systems, a lower opening pressure may be required to ensure that the valve can respond quickly and avoid fluid backflow. Nantong Samson Precision Industry Co., Ltd. (Samson), as a manufacturer focusing on industrial valves and accessories, is well aware of the diverse requirements for check valve opening pressure in different application scenarios. The company provides a wide range of customized services to help customers choose the most appropriate opening pressure based on specific fluid system conditions to ensure system stability and efficiency.

Samson's technical team works closely with customers to gain an in-depth understanding of their fluid system requirements and uses professional design and engineering technology to design check valves that meet various market needs. Samson not only provides standard products, but also can customize designs according to customers' special requirements to meet the needs of various industrial and commercial applications.

Reasonable opening pressure can also extend the service life of the valve and reduce maintenance frequency and cost. Too low opening pressure may cause the valve to open frequently and increase valve wear; while too high opening pressure may cause the system pressure to be too high, thus affecting the stability of the system. Therefore, choosing the right opening pressure is the key to improving system efficiency and ensuring safe operation of equipment.

3. How does stainless steel improve the performance of check valves?

The performance advantages of stainless steel check valves, especially in high temperature, high pressure and corrosive environments, make them the preferred products in many industrial fields. Compared with other materials, high-quality stainless steel not only has excellent corrosion resistance, but also can withstand high temperature and high pressure working environments. Especially in industries such as chemical, petroleum, food processing and pharmaceuticals, factors such as impurities, corrosive substances and high temperature in the fluid often require valves to have higher durability and reliability, and stainless steel is particularly important at this time.

Nantong Samson Precision Industry Co., Ltd. (Samson), as a professional industrial valve manufacturer, has been focusing on the application of stainless steel materials in check valves. Samson uses sophisticated process technology combined with high-quality stainless steel materials to produce check valves that can meet the needs of various harsh working environments. Whether in high temperature environments or in corrosive liquid media, Samson's stainless steel check valves can show excellent durability and ensure the stable operation of the fluid system.

The corrosion resistance of stainless steel enables the check valve to be used for a long time in fluids containing corrosive media such as acids and alkalis without damage, while its strength ensures the stability of the valve under high pressure environments. In addition, with the continuous expansion of industrial applications, especially in the oil, gas and chemical industries, the application demand for stainless steel check valves is increasing. Samson is well aware of the importance of stainless steel check valves in these high-demand industries. Therefore, the company continues to invest in research and development and use higher quality raw materials to ensure that every stainless steel check valve can withstand the test of harsh environments.

In addition to corrosion resistance and high strength, stainless steel materials also have good formability and processability, making the design and manufacture of check valves more precise, thereby improving the sealing and fluid control capabilities of the valves. For industries that require precise flow control and high safety, choosing a check valve made of stainless steel is undoubtedly an ideal choice to improve system performance.

Samson is committed to helping customers solve problems in various fluid systems through advanced technology and high-quality products. With professional manufacturing capabilities and rich industry experience, Samson's check valve products are widely used in many industries around the world and have been highly praised and trusted by customers.