1. What Makes Stainless Steel Instrument Ball Valves Ideal for Precision Control?

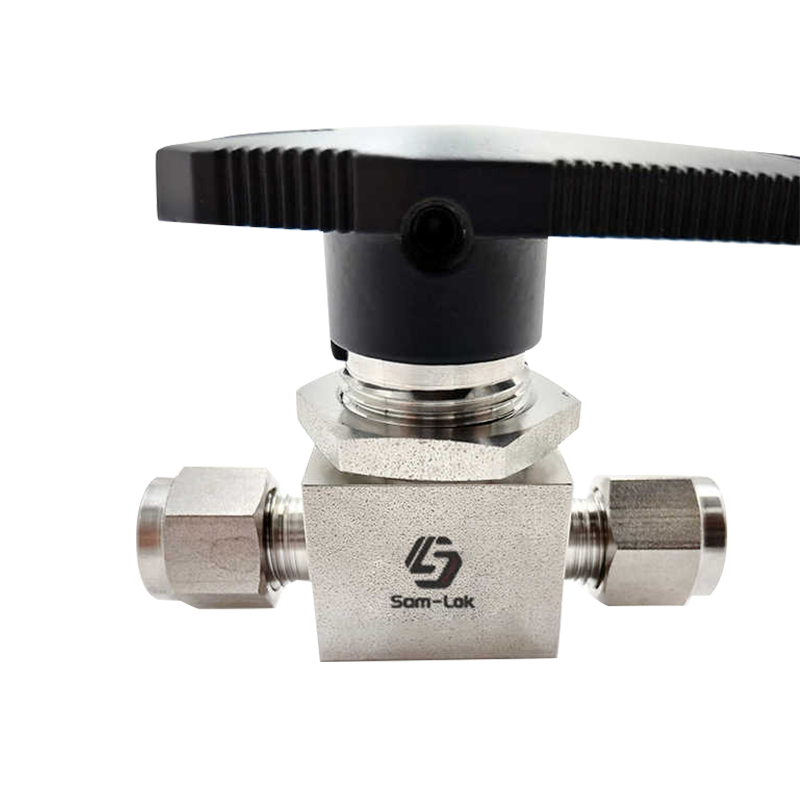

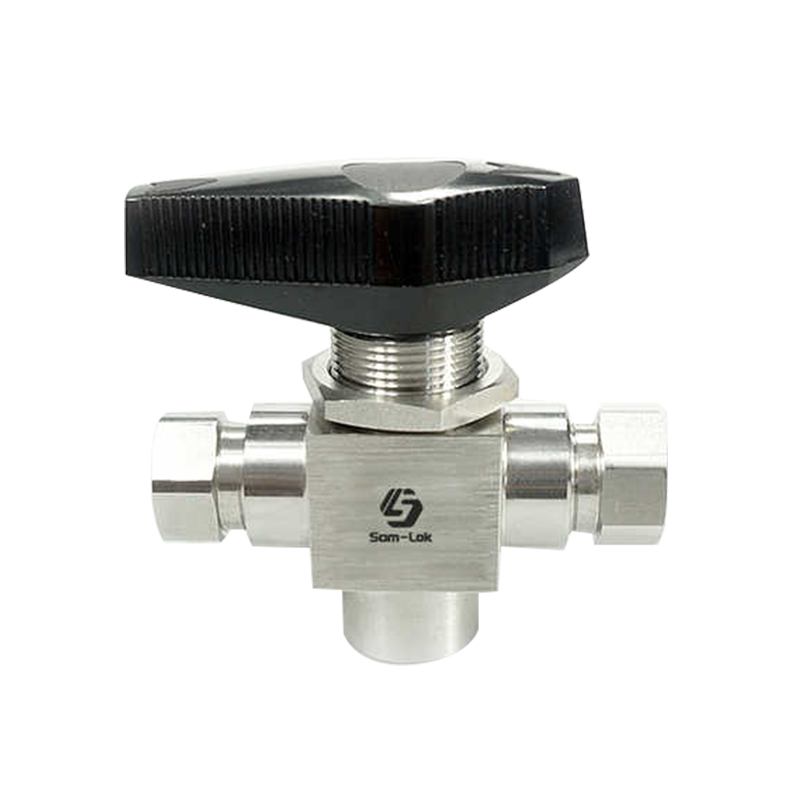

Stainless steel instrument ball valves are designed to provide precise, reliable control over fluid flow in critical systems. At Nantong Samson Precision Industry Co., Ltd., we focus on producing instrument ball valves that feature a spherical ball with a through hole or port. The valve’s design is based on the rotation of the ball: when the valve drive pushes the valve stem to rotate, the ball rotates accordingly. This action either opens or closes the fluid pathway, controlling the flow. The ability to rotate by 90 degrees allows for quick and precise adjustments, making them ideal for applications where fast response times are necessary.

The choice of stainless steel for the valve body offers several key benefits. Stainless steel is known for its excellent corrosion resistance, which is critical in fluid handling systems that deal with aggressive chemicals, high temperatures, or moist environments. The material’s ability to withstand high pressures and extreme temperatures makes it a perfect fit for industries such as oil and gas, chemical processing, and power generation. These properties also ensure that the valves can endure prolonged use without degrading, leading to reduced maintenance costs and longer service life. The simple rotation mechanism of the ball valve makes the valve highly reliable and easy to operate, requiring minimal effort to change flow conditions.

At Nantong Samson Precision Industry Co., Ltd., our stainless steel instrument ball valves are crafted with precision to ensure that they provide tight sealing and accurate control, helping industries to maintain fluid flow with minimal risk of leakage. With our advanced manufacturing process, we ensure that each valve meets stringent quality standards, guaranteeing excellent performance in a wide range of fluid control applications.

2. How Do Stainless Steel Instrument Ball Valves Benefit Various Industries?

Stainless steel instrument ball valves are used across numerous industries due to their exceptional reliability, corrosion resistance, and precise flow control capabilities. These valves are crucial components in systems that require the regulation of fluids or gases, such as chemical plants, power generation facilities, water treatment plants, and food processing industries. At Nantong Samson Precision Industry Co., Ltd., we provide custom solutions for various sectors, ensuring that our stainless steel instrument ball valves meet the specific needs of each industry.

In the chemical and petrochemical industries, stainless steel instrument ball valves are essential for controlling the flow of aggressive chemicals under high pressures and temperatures. The corrosion resistance of stainless steel ensures that the valve will not react with harsh substances, thereby maintaining the integrity of the fluid system and preventing contamination. This is especially important in processes where purity and safety are paramount, such as in pharmaceutical manufacturing or food production.

In oil and gas applications, these valves are employed to regulate the flow of crude oil, natural gas, and other fluids in pipelines and processing equipment. The ability of stainless steel instrument ball valves to withstand high pressures and provide tight seals makes them ideal for such demanding applications. Similarly, in the power generation industry, where steam and high-pressure fluids are common, stainless steel ball valves are used to ensure efficient and reliable flow control, even under extreme operating conditions.

Stainless steel instrument ball valves are also widely used in water treatment and HVAC systems, where their precise flow control is essential for maintaining operational efficiency. In these systems, the ability to shut off or adjust fluid flow accurately is critical to achieving the desired outcomes, whether it’s maintaining water pressure, regulating temperature, or ensuring proper filtration. By selecting the right structural form of the instrument ball valve, industries can tailor their systems to meet specific pressure levels and size requirements.

3. What Are the Key Advantages of Stainless Steel Instrument Ball Valves?

Stainless steel instrument ball valves offer numerous advantages that make them an ideal choice for fluid control applications in various industries. These advantages include durability, ease of maintenance, high performance, and versatility in a range of operating conditions. At Nantong Samson Precision Industry Co., Ltd., we take pride in manufacturing ball valves that deliver these benefits while ensuring top-notch reliability in every system.

One of the most significant advantages of stainless steel instrument ball valves is their durability. Stainless steel’s resistance to corrosion ensures that these valves can withstand exposure to harsh chemicals, high temperatures, and moist conditions without compromising their performance. This durability not only extends the life of the valve but also reduces the need for frequent replacements or repairs, making them a cost-effective solution over time.

Another key advantage is their ease of maintenance. The simple design of stainless steel instrument ball valves, coupled with their tight sealing and smooth operation, minimizes the risk of leaks and malfunctions. Regular maintenance is generally limited to periodic inspections and cleaning, which helps keep the valve operating at peak performance without the need for extensive downtime or service.

The 90-degree rotation feature of these valves allows for quick and precise flow control. This feature is especially beneficial in systems that require rapid adjustments, such as those in chemical processing, manufacturing, and energy production. The ease with which the valve can be operated ensures that processes can be quickly adjusted, optimizing performance and minimizing energy consumption.

In addition to their reliability and ease of use, stainless steel instrument ball valves are versatile. They can be customized to meet various pressure levels and size requirements, making them suitable for a wide range of applications. Whether in high-pressure systems or low-flow operations, stainless steel ball valves can be engineered to fit the specific needs of different industries. At Nantong Samson Precision Industry Co., Ltd., we ensure that our valves are manufactured to meet the highest standards, providing reliable solutions for all your fluid control needs.