1. What are the main features of stainless steel casting valves?

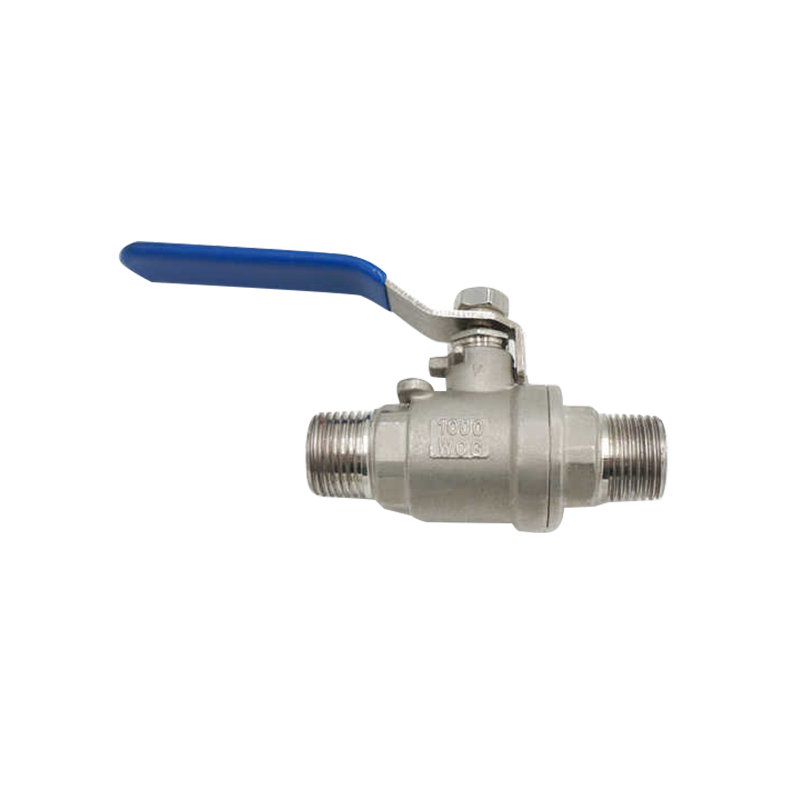

Stainless steel casting valves have occupied a vital position in many industrial fields due to their excellent performance. As Nantong Samson Precision Industry Co., Ltd., we are well aware of the strong advantages of stainless steel casting valves in different environments. The corrosion resistance of stainless steel is one of its most significant features. In highly corrosive environments, such as chemical industries or marine environments, stainless steel valves can effectively prevent corrosion and ensure long-term stable operation of equipment. High temperature resistance is also one of the important advantages of stainless steel valves. Even when working in high temperature environments, these valves can maintain good performance and are not easy to deform or fail. More importantly, stainless steel casting valves have high mechanical strength and impact resistance, and can cope with complex industrial applications. For valves that need to withstand high pressure and high flow rate media for a long time, stainless steel casting valves are particularly suitable.

At Nantong Samson Precision Industry Co., Ltd., we focus on the design, production and supply of stainless steel casting valves with more than 13 years of industry experience, ensuring that each valve meets international standards and provides excellent performance and durability. Our valves are widely used in the fields of petroleum, chemical, power, food processing, pharmaceutical, etc., helping customers improve production efficiency and safety.

2. Why are stainless steel cast valves so important in industrial applications?

The reason why stainless steel cast valves are so important in industrial applications is that they can provide superior performance under extreme working conditions. As a member of Nantong Samson Precision Industry Co., Ltd., we are well aware of the importance of these valves to ensure the normal operation of industrial equipment. Many industrial applications involve high temperature, high pressure, corrosive liquids or gases, which requires valves to have high tolerance and stability. Stainless steel cast valves perform well under these extreme conditions and can effectively avoid failures caused by factors such as corrosion and wear, thereby reducing the cost of repair and replacement.

The casting process of stainless steel cast valves makes them have excellent sealing performance, which can prevent media leakage and ensure the safe operation of equipment. Whether it is in the high-pressure pipelines of the petrochemical industry or the hygienic requirements of the food processing industry, stainless steel cast valves can provide long-lasting reliability and good sealing. Due to the good machinability and corrosion resistance of stainless steel, these valves are usually able to adapt to more complex industrial requirements.

Nantong Samson Precision Industry Co., Ltd. is an ISO-certified company. Our products meet strict quality control standards to ensure that each stainless steel casting valve can meet the needs of the high-end market. Our valves have been exported to Europe, North America, South America, Australia, Russia, the Middle East and Southeast Asia, and are trusted and loved by customers around the world.

3. How to choose a suitable stainless steel casting valve?

When choosing a suitable stainless steel casting valve, you need to consider a number of factors. As Nantong Samson Precision Industry Co., Ltd., we are always committed to providing customized solutions for our customers. Consider the working environment of the valve. Different working environments have different requirements for valves. For example, in a chemically corrosive environment, the corrosion resistance of the valve is crucial; in a high temperature or high pressure environment, the high temperature and pressure resistance of the valve are even more critical. The size and design of the valve should also be selected according to the specific application requirements. When designing, make sure that the valve flow, flow rate and medium type match the valve specifications to ensure its optimal performance.

In addition to the working environment, the sealing performance, durability and ease of installation and maintenance of the valve are also key factors to consider when choosing. Our products from Nantong Samson Precision Industry Co., Ltd. excel in all these aspects. Our valves have strong sealing performance, which can effectively avoid leakage problems and ensure the long-term safe operation of the equipment. At the same time, our valves are simple in design, easy to install and maintain, and reduce operating costs.

When choosing stainless steel cast valves, you must also ensure that they meet relevant industry standards and certifications. This not only ensures the stability of product quality, but also avoids unnecessary risks in long-term use. Every stainless steel cast valve from Nantong Samson Precision Industry Co., Ltd. has passed strict quality inspections and meets ISO certification standards, ensuring that every product received by customers meets international standards.

By working with Nantong Samson Precision Industry Co., Ltd., customers can get products with competitive prices, reliable quality and excellent services to help them succeed in the industry.