1.What Are Ball Valves and How Do They Work?

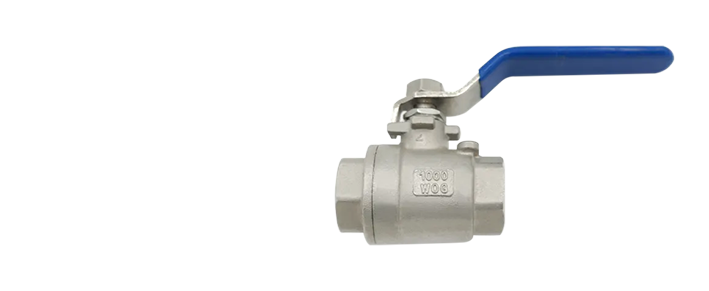

Ball valves are a vital component in fluid control systems, widely utilized in a variety of industries due to their durability, efficiency, and versatility. These valves are designed with a spherical ball that contains a hole or port in the center. When the valve is open, the hole aligns with the pipeline, allowing fluid to pass through. Conversely, when the valve is closed, the ball rotates 90 degrees, blocking the flow of fluid completely.

At Nantong Samson Precision Industry Co., Ltd., we manufacture high-quality ball valves that are engineered for optimal performance across a wide range of industrial applications. Our ball valves are designed for quick operation, minimal leakage, and long-term reliability. Whether it’s for gas, water, or industrial fluids, our valves can efficiently regulate the flow with a smooth and secure shut-off. We understand the importance of maintaining the highest standards in our manufacturing processes, which is why we conduct a first inspection after each production stage and perform random inspections during mass production. This ensures that every ball valve meets customer specifications and international quality standards.

Ball valves are known for their simplicity, but their design also offers remarkable reliability in demanding environments. The main body of the valve typically consists of a full port, which provides unrestricted flow, making it ideal for applications where maximum flow rates are required. Ball valves are also appreciated for their quick quarter-turn operation, which ensures that they can open and close within seconds, making them ideal for systems that need frequent or rapid adjustments. At Nantong Samson Precision Industry Co., Ltd., we prioritize not only the functional design of each valve but also ensure that they are built to withstand high pressure and temperature variations, providing long-lasting service for industries like oil and gas, chemical processing, and water treatment.

2.Key Advantages of Ball Valves in Industrial Applications

Ball valves offer several advantages over other valve types, particularly in terms of ease of use, durability, and performance in high-pressure systems. At Nantong Samson Precision Industry Co., Ltd., we focus on delivering these benefits to our customers by adhering to strict quality control measures throughout the manufacturing process. One of the primary advantages of ball valves is their ability to provide a tight seal, preventing leaks even under high-pressure conditions. This is crucial in industries like petrochemicals, where leakage can lead to safety hazards and significant downtime.

Ball valves require minimal maintenance and offer low torque, which reduces the effort needed to operate the valve and enhances energy efficiency. This low torque requirement also means that ball valves are ideal for automated systems, where consistent performance is critical. Our commitment to quality means that every ball valve undergoes 100% full inspection according to customer requirements and international standards before it is shipped, ensuring that each valve performs as expected.

Another key advantage of ball valves is their versatility. They are compatible with a wide range of fluids, including water, oil, natural gas, and even aggressive chemicals. The corrosion-resistant materials we use in the manufacturing process, such as stainless steel, ensure that the valves maintain their integrity over time. Moreover, ball valves are suitable for both low and high-pressure applications, making them a go-to solution for various industries, including HVAC, water treatment, pharmaceuticals, and more.

At Nantong Samson Precision Industry Co., Ltd., we offer both customized and standard-size ball valves to meet our customers' specific needs. When quoting, we confirm transaction methods such as FOB, CIF, CNF, or other options, and for mass production, we typically require a 30% advance payment, with the balance paid after the bill of lading is issued. Our payment methods are flexible, including T/T and L/C, ensuring smooth and efficient transactions.

3.Types of Ball Valves and Their Applications

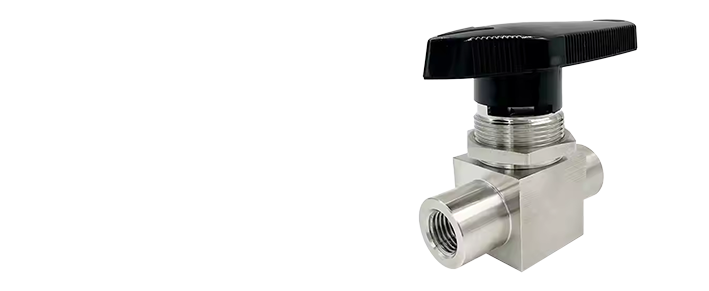

Ball valves come in various designs and configurations, each tailored to specific applications. At Nantong Samson Precision Industry Co., Ltd., we provide an array of ball valve options that suit different industrial requirements. The most common types include:

Floating Ball Valve: In a floating ball valve, the ball is not fixed but rather "floats" within the valve body. It is supported by two seals and is commonly used in low to medium pressure systems. This design offers a more cost-effective solution while still providing reliable shut-off capabilities.

Trunnion Mounted Ball Valve: Unlike the floating ball valve, the ball in a trunnion mounted valve is fixed in place by a support structure. This type of valve is ideal for high-pressure and large-diameter pipelines. It is designed to reduce the mechanical stress placed on the ball and seals, providing greater stability and performance in demanding applications.

V-Port Ball Valve: The V-port ball valve has a "V" shaped ball that allows for precise throttling and control of the flow rate. It is commonly used in applications where accurate flow regulation is critical, such as in chemical processing or high-flow systems.

Multi-port Ball Valve: These valves feature more than two ports, which allow for the redirection of flow in multiple directions. Multi-port ball valves are ideal for systems that need to manage flow across multiple lines or to facilitate the mixing of different fluids. They are commonly used in applications like multi-pipe systems and diverter processes.