1.Why Are Stainless Steel 37° Flare Fittings Crucial for High-Pressure Systems?

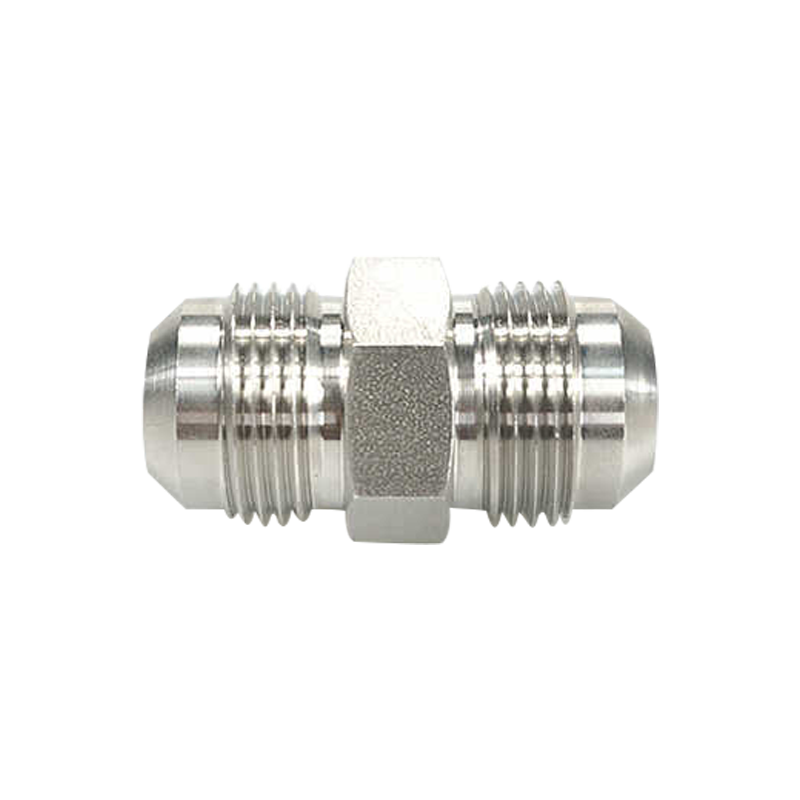

37° Flare Fittings, typically made of robust materials such as brass or stainless steel, are indispensable components in high-pressure hydraulic systems. At Nantong Samson Precision Industry Co., Ltd., we specialize in manufacturing these fittings with precision and attention to detail, ensuring they meet the stringent requirements of various industrial applications. The 37° flare angle provides superior sealing capabilities, making these fittings ideal for systems that endure high pressures, such as hydraulic transmissions.

These fittings play a critical role in ensuring the stable circulation of hydraulic fluids in high-pressure systems. The superior sealing properties of 37° Flare Fittings prevent leaks, which could lead to system failure or loss of performance. By securing pipes tightly, they maintain a consistent flow of hydraulic oil, even under extreme pressure conditions. This makes them particularly valuable in industries such as aerospace, automotive, and heavy machinery, where precision and safety are paramount.

At Nantong Samson, we understand the importance of durability and reliability in high-pressure applications. With over 13 years of industry experience, our stainless steel 37° Flare Fittings are manufactured to provide outstanding performance and longevity. As a China Stainless Steel 37° Flare Fittings Manufacturer, we utilize ISO-certified quality control processes, ensuring that our products consistently meet or exceed industry standards. Our commitment to excellence in manufacturing has earned us the trust of wholesalers, retailers, and service providers worldwide, with our products being exported to regions such as Europe, North America, and Southeast Asia.

2.How Do 37° Flare Fittings Contribute to the Efficiency of Pneumatic and Gas Systems?

37° Flare Fittings are not only integral to hydraulic systems but also play a significant role in pneumatic and gas systems. These fittings are specifically designed to connect gas pipes, providing a high level of sealing performance to prevent gas leakage. In systems where gas flow is critical—such as in compressed air systems, natural gas pipelines, and gas delivery networks—37° Flare Fittings ensure that the flow remains uninterrupted and efficient.

At Nantong Samson Precision Industry Co., Ltd., we take pride in manufacturing stainless steel 37° Flare Fittings that offer excellent sealing performance, even in the most demanding environments. The 37° flare angle allows for a tight and reliable connection between pipes, reducing the risk of leaks that could lead to system failures or safety hazards. In pneumatic systems, this capability is crucial for maintaining consistent pressure and flow, ensuring that the system operates efficiently and safely.

Whether used in industrial air compressors or gas supply networks, the reliability of 37° Flare Fittings is essential to the overall performance of pneumatic systems. At Nantong Samson, we leverage our years of experience to provide products that stand up to the demands of gas systems, offering both cost-effective solutions and peace of mind. As a leading Stainless Steel 37° Flare Fittings Supplier, our products are trusted by clients worldwide, from Europe to South America, thanks to their proven reliability, precision, and durability.

3.What Makes Stainless Steel 37° Flare Fittings Ideal for Automotive Hydraulic and Fuel Systems?

In the automotive industry, 37° Flare Fittings are crucial for ensuring the integrity and performance of hydraulic and fuel systems. These fittings are used to connect various components in a vehicle's hydraulic and fuel systems, where high temperature and high pressure are common. Whether in hydraulic transmissions, power steering systems, or fuel delivery systems, the ability to withstand extreme conditions is vital to maintaining safety and efficiency.

At Nantong Samson Precision Industry Co., Ltd., we understand that automotive systems require high-quality, durable components. Our stainless steel 37° Flare Fittings are engineered to provide precise, leak-proof connections that can withstand the harsh conditions typically found in automotive applications. The 37° flare angle allows for a secure and tight seal, ensuring that hydraulic fluids and fuel are safely contained, preventing leaks that could lead to system failures, fire hazards, or other safety risks.

These fittings are also highly resistant to corrosion, which is essential in automotive systems exposed to varying temperatures and harsh environments. Whether it's a high-pressure fuel system or a hydraulic braking system, our stainless steel 37° Flare Fittings offer excellent resistance to corrosion, ensuring long-lasting performance and reliability.

Nantong Samson has been serving the automotive industry for over 13 years, and we are proud to be a trusted manufacturer and supplier of 37° Flare Fittings. Our products meet ISO standards, and we ensure strict quality control at every step of the manufacturing process. This dedication to quality, combined with our exceptional service and competitive pricing, has allowed us to build strong partnerships with clients worldwide. Our 37° Flare Fittings are used in a variety of automotive applications, from passenger vehicles to heavy machinery, and are highly regarded for their precision, reliability, and durability.